Basic Structure and Function of Refrigerated Displayer Refrigerated Displayer, as indispensable equipment in modern reta...

READ MORE-

-

With the increasing demand for commercial refrigeration equipment, counter chillers, as an important type of refrigerati...

READ MORE -

Cooler showcases, an indispensable piece of equipment in modern commerce, are widely used in supermarkets, convenience s...

READ MORE -

In the modern foodservice industry, refrigeration equipment plays a crucial role. Whether it's a large restaurant, hotel...

READ MORE -

In the catering, retail, and food service industries, the efficiency of refrigeration equipment directly impacts product...

READ MORE

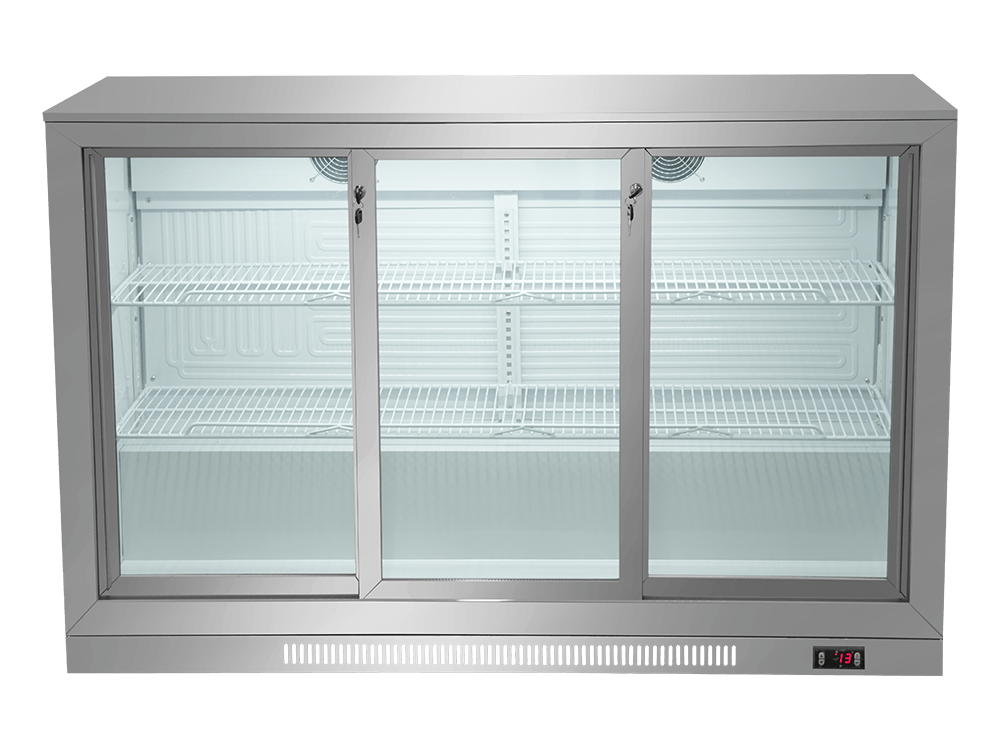

What are the maintenance and cleaning requirements for a stainless steel back bar cooler?

A stainless steel back bar cooler is a significant investment for any bar, restaurant, or hospitality venue. Its gleaming exterior projects an image of professionalism and cleanliness, while its primary function—keeping beverages perfectly chilled—is vital for customer satisfaction and operational efficiency. However, to ensure this essential piece of commercial refrigeration equipment performs reliably for years to come, a consistent and thorough maintenance and cleaning regimen is non-negotiable. Proper care not only preserves the unit’s aesthetic appeal but also optimizes its energy efficiency, prevents costly repairs, and upholds stringent food safety standards.

Understanding the importance of this upkeep begins with recognizing the dual threats of neglect: cosmetic degradation and mechanical failure. Spills, fingerprints, and mineral deposits can quickly mar the sleek surface of stainless steel, while dust and debris accumulating on the condenser coil force the compressor to work harder, leading to increased energy consumption and potential breakdowns. Furthermore, in a busy bar environment, the interior is susceptible to microbial growth if not sanitized regularly, posing a risk to beverage safety. Therefore, a proactive approach to maintenance is far more cost-effective than reactive repairs. It is worth noting that manufacturers who invest in robust engineering, such as those with modern production facilities and certifications like CE and CCC, design their units for durability, but this inherent reliability must be partnered with responsible care from the owner.

The fundamentals of cleaning the stainless steel exterior

The exterior of the cooler is its public face, and maintaining its pristine appearance is crucial for brand image. Stainless steel is chosen for its corrosion resistance and durability, but it is not entirely impervious to damage. The key to preserving its finish is using the correct cleaning techniques and materials. The most important rule is to always wipe in the direction of the metal’s “grain,” which is the visible brushed lines on the surface. Wiping against the grain can cause microscopic scratches that accumulate over time, dulling the finish.

For daily cleaning, a simple yet effective method suffices. Begin by using a soft, damp microfiber cloth to remove loose dust, fingerprints, and light spills. For more stubborn smudges or sticky residues, a mild detergent solution can be used. Mix a few drops of a pH-neutral dish soap with warm water. Dip the cloth into the solution, wring it out thoroughly so it is only damp—not wet—and wipe the surface. Immediately afterward, rinse the cloth with clean water, wring it out, and wipe the area again to remove any soapy film. Finally, use a separate dry microfiber cloth to buff the surface to a streak-free shine. This simple routine, performed at the end of each shift, will maintain the cooler’s visual appeal with minimal effort.

It is critical to avoid harsh chemicals. Abrasive cleaners, scouring powders, steel wool, and chloride-based cleaners (like bleach) should never be used on stainless steel. These substances can permanently etch, scratch, or discolor the metal. Similarly, glass cleaners often contain ammonia, which can be too harsh for some stainless steel finishes. If a more powerful cleaner is necessary to remove a particularly difficult stain, a dedicated stainless steel cleaner or polish is the safest option. These products are specifically formulated to clean and protect the surface, often leaving behind a thin protective layer that helps repel fingerprints. For establishments in areas with hard water, special attention should be paid to cleaning off water spots promptly, as the minerals can etch the surface if left to dry.

Interior cleaning and sanitation protocols

The interior of the stainless steel back bar cooler is where hygiene is paramount. A clean interior ensures that beverages are stored in a safe environment and prevents cross-contamination of odors. The frequency of interior cleaning depends on the volume of use, but a thorough cleaning should be conducted at least weekly.

The process begins with preparation. To ensure safety and efficiency, the unit should be unplugged from the electrical outlet. If this is not feasible, the temperature control should be turned to the “off” position. All contents—bottles, cans, and any storage bins—must be removed and placed in a temporary cooling solution to maintain their temperature. Any removable components, such as shelves, racks, and drip trays, should be taken out. These parts can be washed separately in a sink with warm, soapy water, rinsed thoroughly, and air-dried.

With the interior empty, the cleaning can commence. Using a solution of warm water and a mild detergent, wipe down every interior surface: the walls, ceiling, floor, and door gaskets. Pay close attention to corners and crevices where spills and debris can accumulate. For sanitation, especially in high-traffic food service businesses, a food-safe sanitizer is recommended. A solution of two tablespoons of baking soda mixed with a quart of warm water is an effective and gentle sanitizing alternative. Alternatively, a diluted white vinegar solution can help eliminate odors and disinfect. After applying any cleaning or sanitizing agent, it is imperative to rinse the surfaces with a cloth dampened with clean water to remove any residue. Finally, dry all surfaces completely with a clean towel before replacing the shelves and restocking the beverages. Allowing the interior to air dry fully before restoring power is a best practice to prevent moisture buildup.

The door gaskets, the rubber seals around the door, require special attention. These components are crucial for maintaining an airtight seal, which directly impacts temperature consistency and energy efficiency. Wipe them regularly with warm, soapy water and inspect them for signs of wear, tear, or cracking. A damaged gasket will allow cold air to escape, forcing the compressor to run continuously. To test the seal, close the door on a piece of paper; if the paper can be pulled out easily with the door closed, the gasket may need adjustment or replacement.

Essential maintenance for optimal performance

Beyond cleaning, certain maintenance tasks are critical for the mechanical health of the stainless steel back bar cooler. The most important of these is condenser coil care. The condenser coil is responsible for releasing heat from the refrigeration system. In the dusty environment of a bar or kitchen, these coils can become clogged with dust, grease, and pet hair. A dirty coil cannot dissipate heat effectively, causing the compressor to overwork, which leads to higher electricity bills and can precipitate a system failure.

The location of the condenser coil varies by model—it may be on the back of the unit, underneath it, or accessed from the front behind a grille. The owner’s manual will provide specific instructions. Generally, coils should be cleaned every three to six months, or more frequently in particularly dusty environments. Before cleaning, always disconnect the power. For coils that are easily accessible, using a soft brush to loosen the debris followed by a vacuum cleaner with a brush attachment is effective. For more heavily soiled coils, a commercial condenser coil cleaner can be used. These sprays foam up to lift the grime, which is then rinsed away carefully, ensuring that water does not come into contact with electrical components. This task, while technical, is one of the most impactful actions an operator can take to ensure the long-term reliability and efficiency of their beverage cooling equipment.

Another key maintenance aspect is managing the defrost system. Many modern back bar coolers feature an automatic defrost cycle. However, it is still important to monitor for ice buildup, especially on the evaporator coil inside the unit. Excessive ice can impede airflow and cooling. If a manual defrost is required, simply unplug the unit, remove all contents, and allow the ice to melt naturally. Placing towels inside can help manage the water. Never use sharp objects to chip away ice, as this can easily damage the cooling coils, resulting in a costly refrigerant leak.

Finally, general operational vigilance is required. Listen for unusual noises from the compressor or fans, as these can be early indicators of a problem. Ensure that the unit is standing level, as an uneven stance can cause door misalignment and strain on the compressor. Keep a log of cleaning and maintenance activities; this not only ensures tasks are not forgotten but also provides valuable records if a warranty claim or service call is needed.

Creating and implementing a maintenance schedule

Knowledge of the required tasks is only effective when applied consistently. The best practice for any establishment is to formalize the maintenance of the stainless steel back bar cooler into a written schedule. This schedule should be clearly posted and assigned to specific staff members to ensure accountability.

The following table outlines a suggested maintenance schedule for a typical high-use commercial setting.

| Task | Frequency | Key Notes |

|---|---|---|

| Exterior wipe-down | Daily | Use a damp microfiber cloth, followed by a dry one. Wipe with the grain. |

| Check door seal | Weekly | Ensure the gasket is clean and pliable. Test the seal with the paper method. |

| Interior cleaning | Weekly | Remove all contents and shelves. Clean and sanitize all surfaces. Dry thoroughly. |

| Inspect for ice buildup | Monthly | Check the evaporator coil. Schedule a manual defrost if necessary. |

| Clean condenser coil | Quarterly (or as needed) | Power off the unit. Brush and vacuum dust and debris. Use coil cleaner if required. |

| General inspection | Semi-Annually | Check for unusual noises, ensure the unit is level, and verify temperature accuracy. |

Adhering to such a schedule transforms maintenance from a reactive chore into a proactive strategy. This disciplined approach directly contributes to the long-term performance of the equipment. It minimizes unexpected downtime during peak service hours, protects the investment by extending the unit’s operational life, and ensures that the energy efficiency promised by modern standards, such as the European A+ level, is actually realized in practice. A well-maintained cooler operates at peak efficiency, which is not only good for the bottom line but also for environmental sustainability.

English

English 中文简体

中文简体 Español

Español عربى

عربى