- Home

- Product

- Island Freezer Series

- Commercail Kitchen Freezer Series

- Back Bar Cooler Series

- Chest Freezer Series

- Deli Cabinet

- Standard Copper Tube Refrigerator

- Non-Magnetic Refrigerator

- Air-Cooled Duck Cabinet

- Ice Maker

- SS Vertical Glass Showcase

- Combo Cabinet

- Refrigerated Display Cases

- Back Bar Coolers

- Beverage Display Coolers

- Undercounters

- Reach-Ins

- About Us

- Solution

- Service

- News

- Contact Us

Web Menu

- Home

- Product

- Island Freezer Series

- Commercail Kitchen Freezer Series

- Back Bar Cooler Series

- Chest Freezer Series

- Deli Cabinet

- Standard Copper Tube Refrigerator

- Non-Magnetic Refrigerator

- Air-Cooled Duck Cabinet

- Ice Maker

- SS Vertical Glass Showcase

- Combo Cabinet

- Refrigerated Display Cases

- Back Bar Coolers

- Beverage Display Coolers

- Undercounters

- Reach-Ins

- About Us

- Solution

- Service

- News

- Contact Us

Product Search

Exit Menu

Why is Commercial Refrigeration Equipment Crucial for Food Safety?

2025.12.15

2025.12.15

Industry News

Industry News

In the modern business environment, refrigeration equipment is becoming increasingly important as an indispensable part of industries such as catering, retail, and warehousing. Whether it's maintaining food freshness or ensuring quality and safety, commercial refrigeration equipment plays a crucial role. From supermarket display cases to restaurant refrigerators, commercial refrigeration equipment needs to possess not only powerful performance but also stability and efficiency to meet the complex demands of commercial operations.

Classification and Characteristics of Commercial Refrigeration Equipment

Commercial refrigeration equipment comes in a wide variety of types, with different designs and functions depending on the application and needs. Common commercial refrigeration equipment mainly includes refrigerated display cases, freezers, cold storage rooms, and specialized refrigerated trucks.

Refrigerated Display Cases

Refrigerated display cases are widely used in supermarkets, convenience stores, pharmacies, and other retail industries, typically for displaying and storing perishable foods such as meat, dairy products, and beverages. These devices need to have not only good cooling effects but also be aesthetically pleasing and easy to access to attract customers and maintain the good condition of the food.

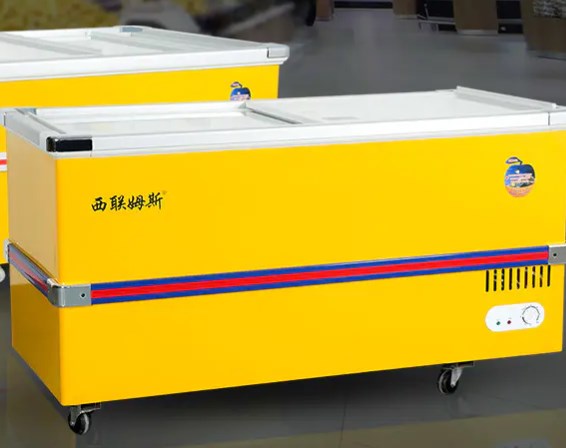

Freezers

Freezers are mainly used for storing food that requires low-temperature preservation, such as ice cream and frozen foods. Their design usually focuses on low-temperature performance and large capacity to meet the needs of long-term frozen storage. Efficient freezers can also help reduce energy consumption, thereby reducing operating costs while ensuring food safety.

Cold Storage Rooms

Cold storage rooms are core equipment in large-scale commercial operations, commonly used in large warehouses, wholesale markets, and logistics centers. The temperature control system of cold storage rooms is usually more precise, allowing for different temperatures to be set in different areas to meet the storage needs of various types of food. Furthermore, modern cold storage rooms are increasingly focusing on intelligent management, using networking technology to achieve temperature monitoring and data recording, ensuring the quality and safety of food.

Refrigerated Trucks

Refrigerated trucks are indispensable equipment in the logistics and distribution chain, especially in the food distribution industry. Refrigerated trucks can maintain a low-temperature environment during transportation, preventing food from spoiling during transit. These devices usually require efficient refrigeration systems and user-friendly designs to improve transportation efficiency and safety.

Technical Requirements and Performance Standards of Commercial Refrigeration Equipment

As food safety issues receive increasing attention, the technical requirements and performance standards for commercial refrigeration equipment have become more stringent. The cooling performance of refrigeration equipment is one of its most critical indicators. Refrigeration systems typically utilize high-efficiency compressors and condensers to ensure stable operation under varying external environmental conditions. To improve energy efficiency, many commercial refrigeration units also employ variable frequency technology and intelligent temperature control systems, allowing the equipment to maintain low energy consumption even under high load conditions.

The materials and structural design of the equipment also determine its performance and lifespan. Commercial refrigeration equipment typically uses corrosion-resistant and temperature-resistant materials such as stainless steel or aluminum alloy. These materials effectively prevent corrosion or aging during long-term use. The sealing of the equipment is also a crucial factor affecting its cooling performance; a good sealing design prevents cold air leakage and ensures efficient operation.

In addition, commercial refrigeration equipment must possess good safety and ease of maintenance. The electrical and temperature control systems must comply with relevant safety standards to prevent electrical failures or temperature anomalies. The equipment should also be easy to clean and maintain regularly, reducing the incidence of equipment failures and extending its service life.

Energy Efficiency and Environmental Technologies in Commercial Refrigeration Equipment

With increasing environmental awareness and rising energy costs, more and more commercial refrigeration equipment manufacturers are focusing on energy efficiency and environmental technologies. To reduce energy consumption and minimize environmental impact, many devices utilize low-energy compressor systems and high-efficiency insulation materials. The introduction of intelligent temperature control systems allows the equipment to automatically adjust its operating status based on usage needs, thereby achieving energy savings.

The choice of refrigerant for refrigeration equipment has also become an important aspect of environmental technology. In recent years, low-GWP (Global Warming Potential) refrigerants such as R290 and R600a have gradually replaced traditional R134a and R404a refrigerants, becoming more environmentally friendly options. These refrigerants not only do not deplete the ozone layer but also have significantly lower greenhouse gas emissions than traditional refrigerants, complying with international environmental standards.

Frequently Asked Questions (FAQ)

1. How to choose the right commercial refrigeration equipment?

When choosing commercial refrigeration equipment, you first need to determine the type and specifications of the equipment based on your business needs. For example, the catering industry may require more flexible display cabinets, while large supermarkets may prioritize the capacity and temperature control accuracy of cold storage. You also need to consider the equipment's energy efficiency, ease of maintenance, and brand reputation.

2. What is the lifespan of commercial refrigeration equipment?

The lifespan of commercial refrigeration equipment is typically related to its brand, maintenance, and operating environment. Generally, high-quality equipment can last 8 to 15 years with proper maintenance. Regular cleaning, checking the temperature control system, and replacing worn parts can help extend the equipment's lifespan.

3. How to reduce the energy consumption of commercial refrigeration equipment?

Methods to reduce energy consumption include choosing energy-efficient equipment, maintaining good sealing of the equipment, and regularly cleaning the condenser and evaporator.

4. What to do if commercial refrigeration equipment malfunctions?

When commercial refrigeration equipment malfunctions, first check if the temperature settings and power connection are normal. If you cannot resolve the problem yourself, it is recommended to contact professional repair services for inspection and repair. Stop using the equipment immediately and address the issue to avoid further damage.

The selection and maintenance of commercial refrigeration equipment are crucial for ensuring food safety and quality. When purchasing, considering factors such as equipment performance, energy efficiency, brand reputation, and after-sales service will help businesses choose the most suitable equipment, thereby improving operational efficiency, reducing costs, and ensuring customer food safety and satisfaction.

News categories

Product categories

Exhibition Information

-

How do Refrigerated Displayer enhance a business's sales and customer experience?

Jan 22,2026 -

How Counter Chillers Work: Why are they the first choice for commercial cold chain equipment?

Jan 15,2026 -

How can Cooler Showcases enhance product display and increase customer purchase intent?

Jan 08,2026 -

How Does Catering Refrigeration Equipment Help Improve Service Quality in the Foodservice Industry?

Jan 01,2026

Related News

![]() +86-153 0659 4509

+86-153 0659 4509

![]() +86-(0)573-8796 5558

+86-(0)573-8796 5558

![]() zjxingbao@gmail.com

zjxingbao@gmail.com

![]() No. 10 Baisha Road, Lianhang Development Zone, Chang'an Town, Haining City, Zhejiang China 314423

No. 10 Baisha Road, Lianhang Development Zone, Chang'an Town, Haining City, Zhejiang China 314423

Mobile QR Code

Copyright © Zhejiang Xingbao Electrical Appliance Co., Ltd. All Rights Reserved. Custom Commercial Refrigerator Factory

English

English 中文简体

中文简体 Español

Español عربى

عربى